Wm. Coulthard & Co. Ltd

Unit L1,

Duchess Avenue

Kingmoor Park, Carlisle

CA6 4SN

T: +44(0)1228 672175

F: +44(0)1228 672274

E: sales@wmcoulthard.com

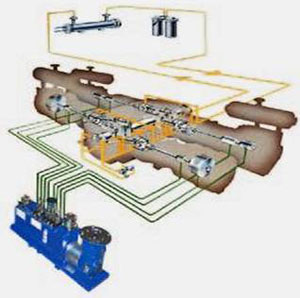

Pump-to-Point

Wm Coulthard & Co provides systems that give the customer precisely what they require.

Some customers prefer a Pump-to-Point arrangement:

Lubrication points are served by individual pump units. This straight forward system enables the flow/volume to an individual lubrication point to be adjusted without affecting any other. Maintenance and replacement tends to be easier and a failure of flow in a pump unit only affects one point, the others continue to be lubricated. Our standard pump units are suitable for up to 410 bar (6000 PSI)

We offer 3 sizes of pump units with plungers being 3/16”, 1/4” and 5/16” diameters. This, together with the rotational speed of the lubricator and the plunger stroke length provides a range of volumes suitable for most operations.

Very large flows can be achieved using a manifold to connect the outputs of multiple pump units.

Similarly, for very small flows, the output from a pump unit can be split between two or more points using a balancing valve to ensure the correct proportion of oil to each receiving point.

Advantages of Pump-to-Point:

- Simple concept

- Each point has individually adjustable oil delivery

- Handles large pressure differential between points

- Only 1 point affected by pump inactivity

- Straight-forward to engineer, implement and maintain

Disadvantages of Pump-to-Point:

- No automatic monitoring of each lubrication point